Dry cleaning systems for workpieces – Precise, dry, efficient

Our dry cleaning systems enable gentle, economical and completely dry cleaning of workpieces of all kinds – without chemicals and without wet media.

The systems are used wherever components need to be reliably cleaned of oils, emulsions, chips and production residues before the next production step.

By using targeted air flows, contour-adapted suction forms, rotating clamping systems and powerful vacuum extraction, our systems clean both individual parts and series components gently and reproducibly.

The systems can be flexibly integrated into existing production lines and are ideal for highly automated production environments.

Why dry cleaning? Advantages at a glance

- Clean workpieces without wet media or chemicals

- Gentle treatment of sensitive surfaces

- Significant reduction in rejects and rework

- Energy and resource-saving operation

- Significantly lower maintenance requirements compared to wet cleaners

- Easy integration into automated production lines With our dry cleaning systems, you can create optimum conditions for subsequent assembly processes, laser marking and even an extension of the service life of existing washing systems.

- Integrated preservation device is possible

Cleaning process - how our technology works

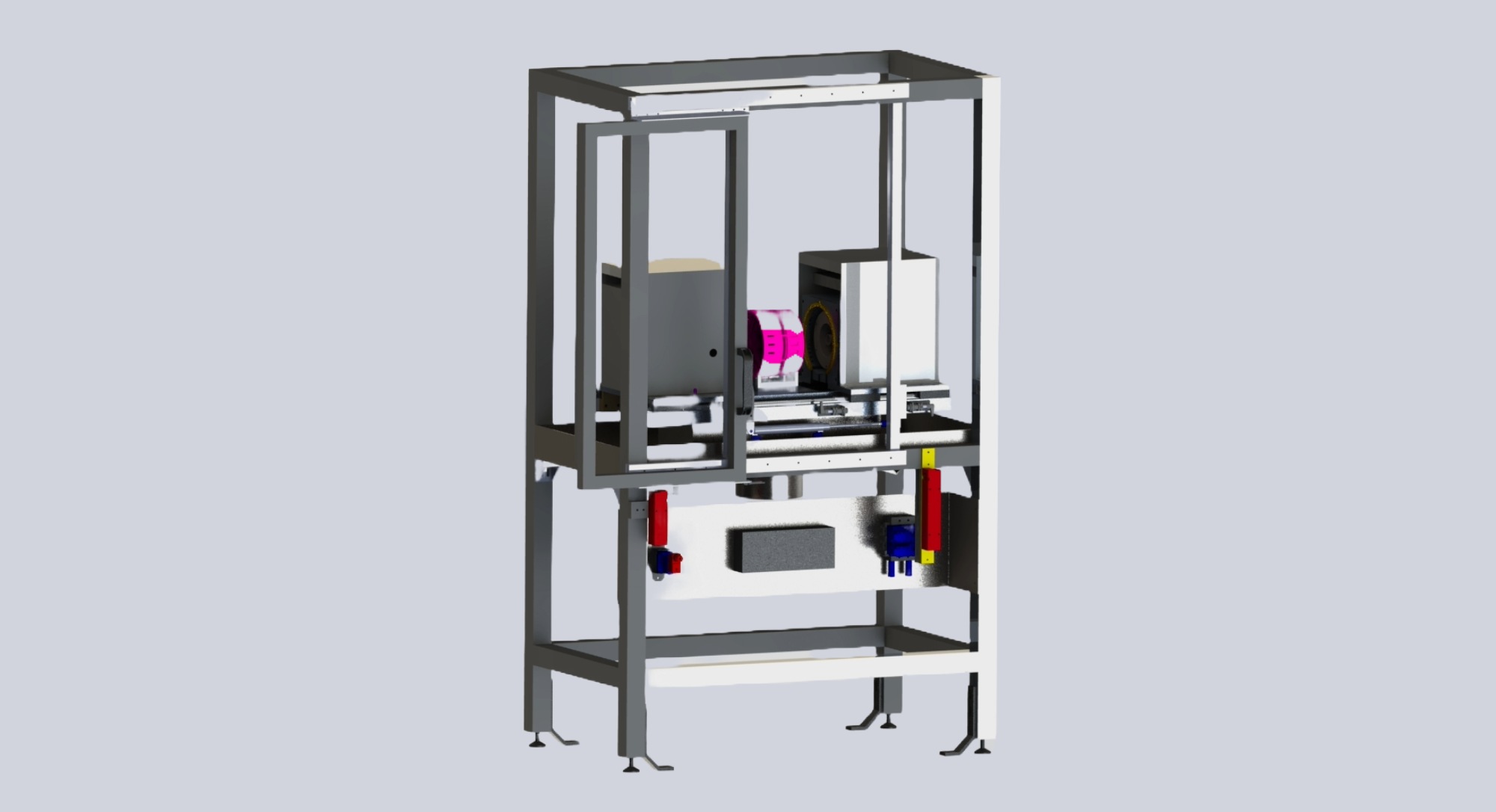

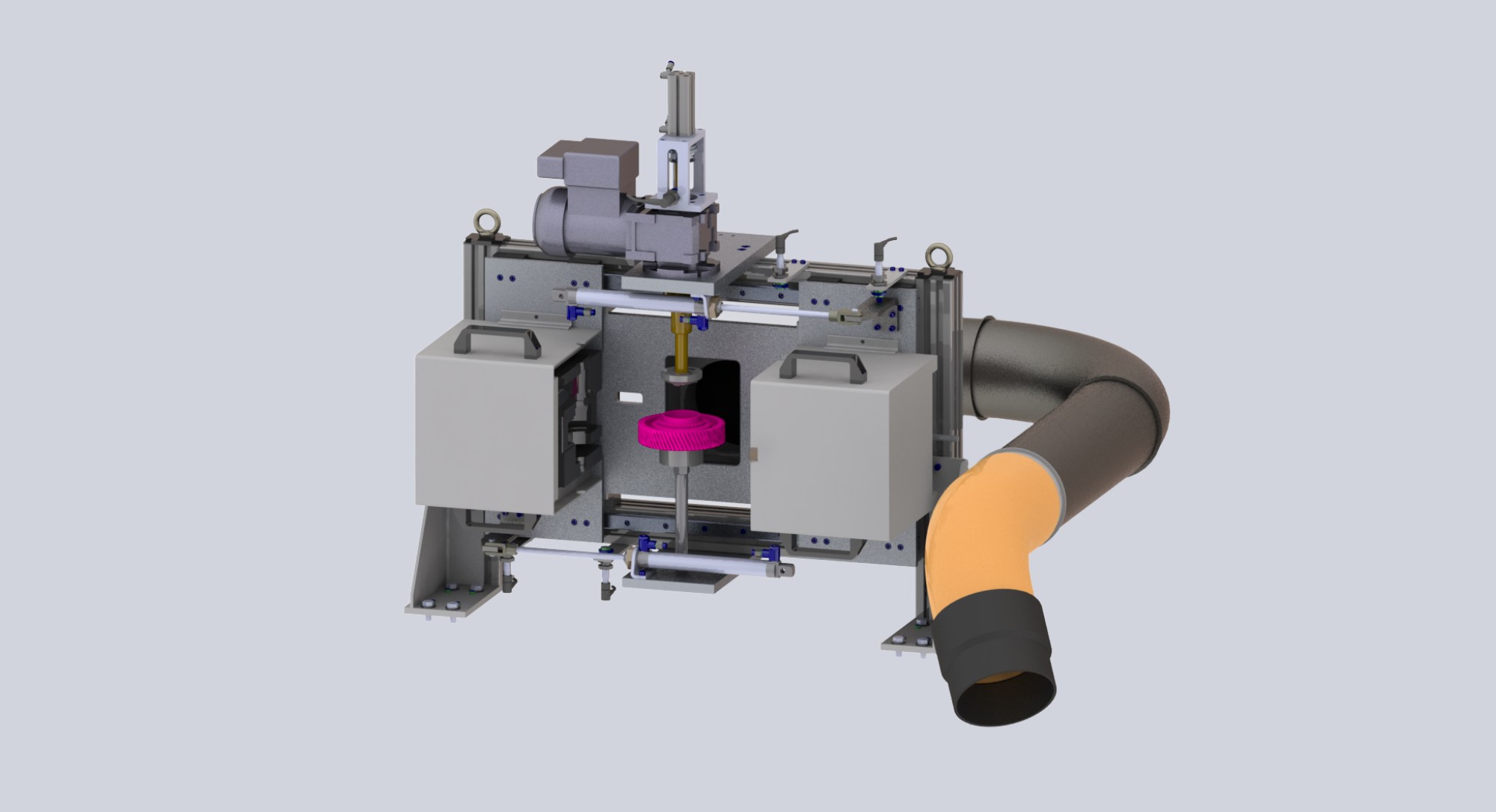

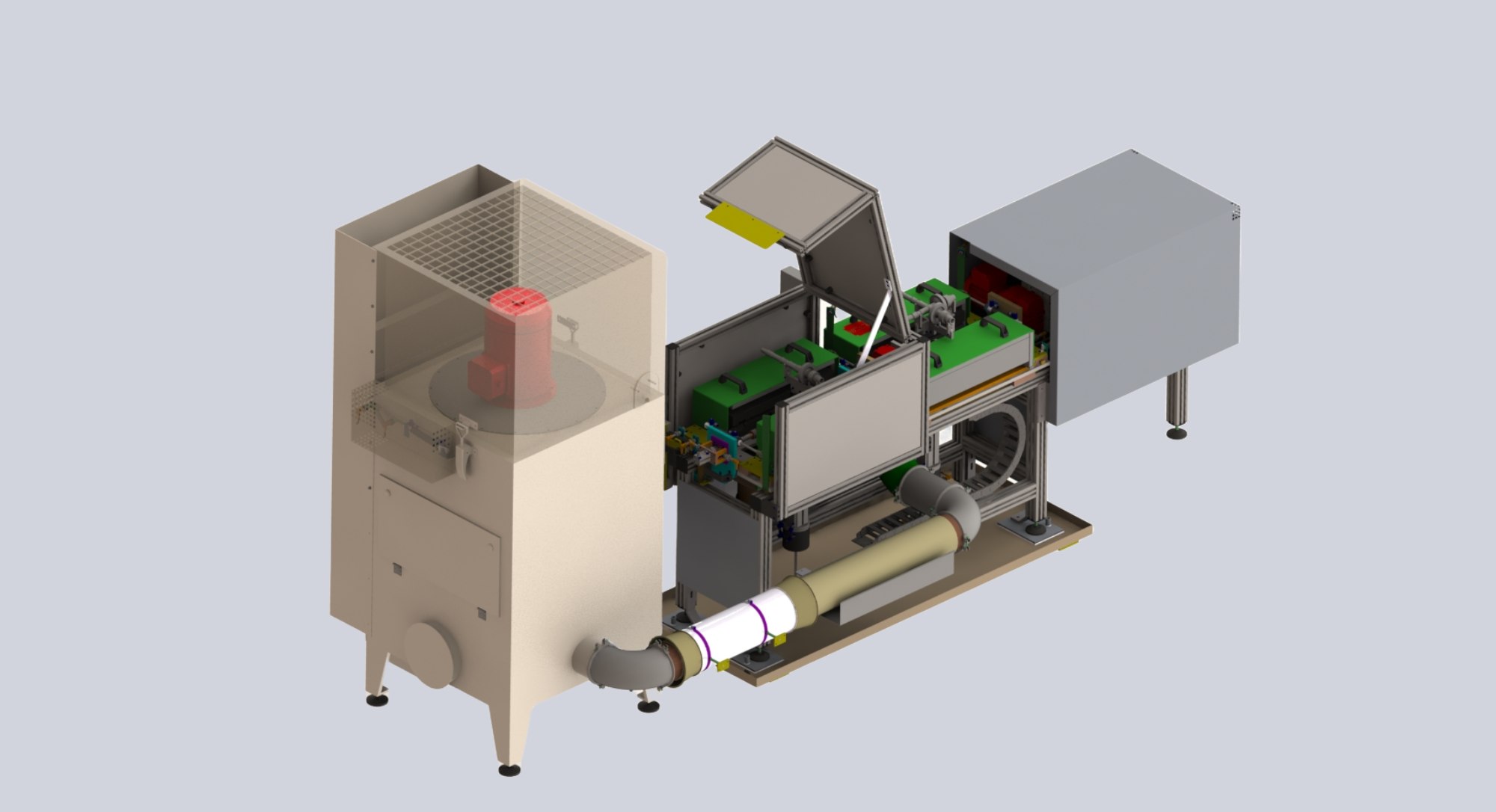

1. cleaning station for rotating components (example: gear shaft)

Workpieces are automatically transferred to storage prisms by a customer-side transport system.

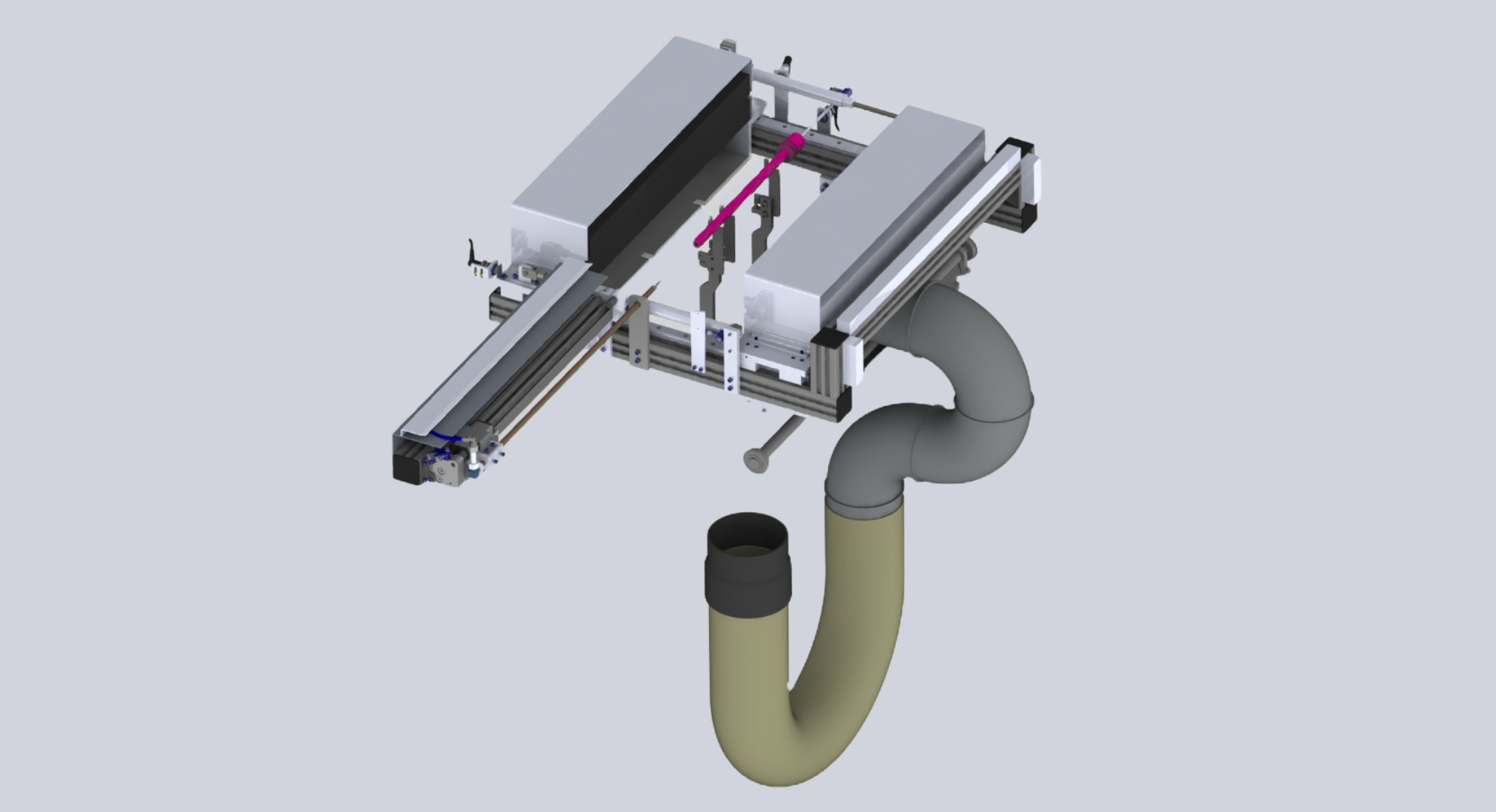

In the next step, they are clamped between the motor and mandrel, enclosed by contour-adapted suction forms and set in rotation as required.

The cleaning effect is created by:

- a precisely guided air flow along the component contour,

- the internal cleaning by a compressed air blast nozzle on the clamping mandrel,

On completion, the clamping and suction components retract, and the workpiece is automatically transported onwards by the transport system.

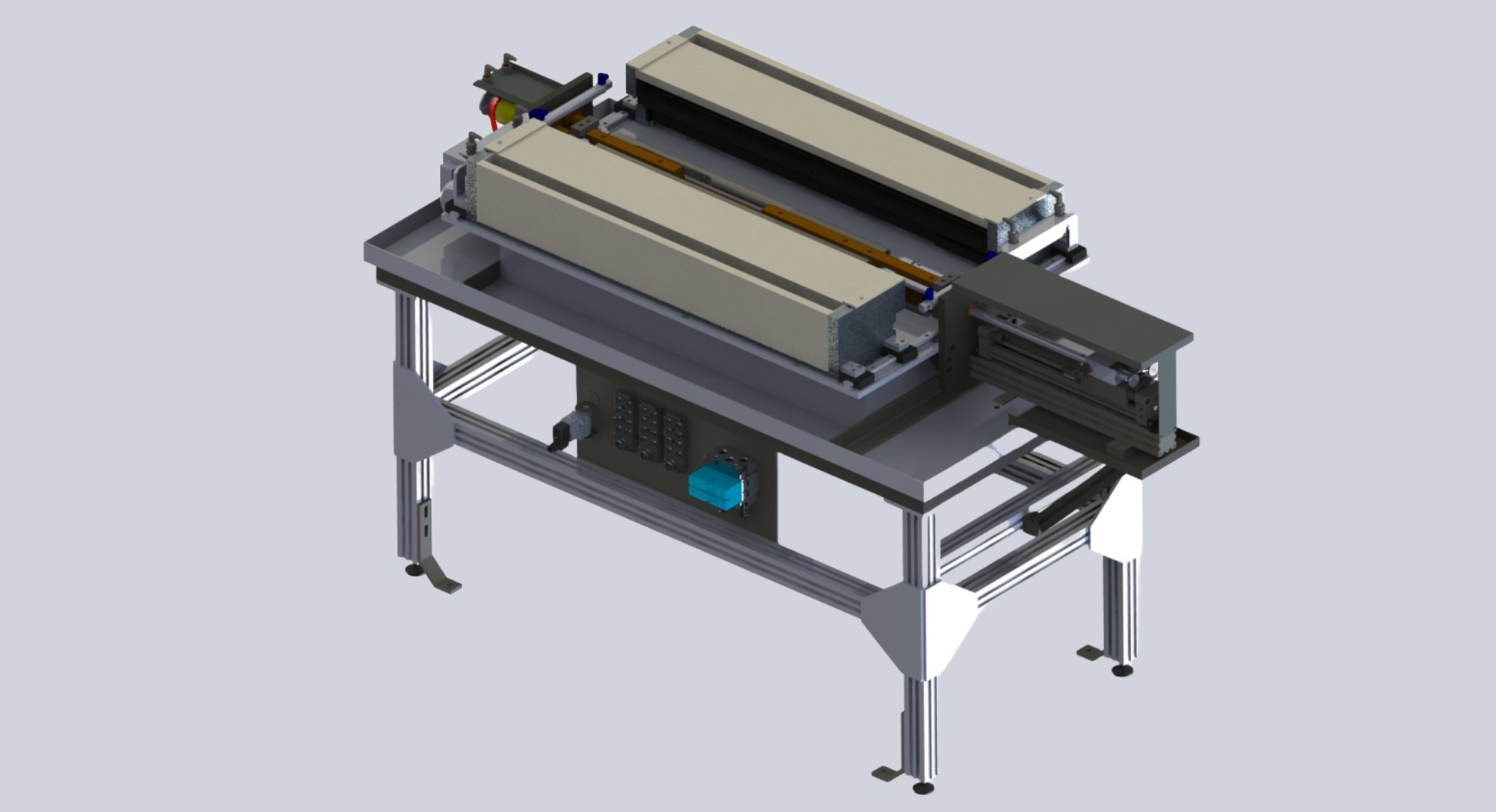

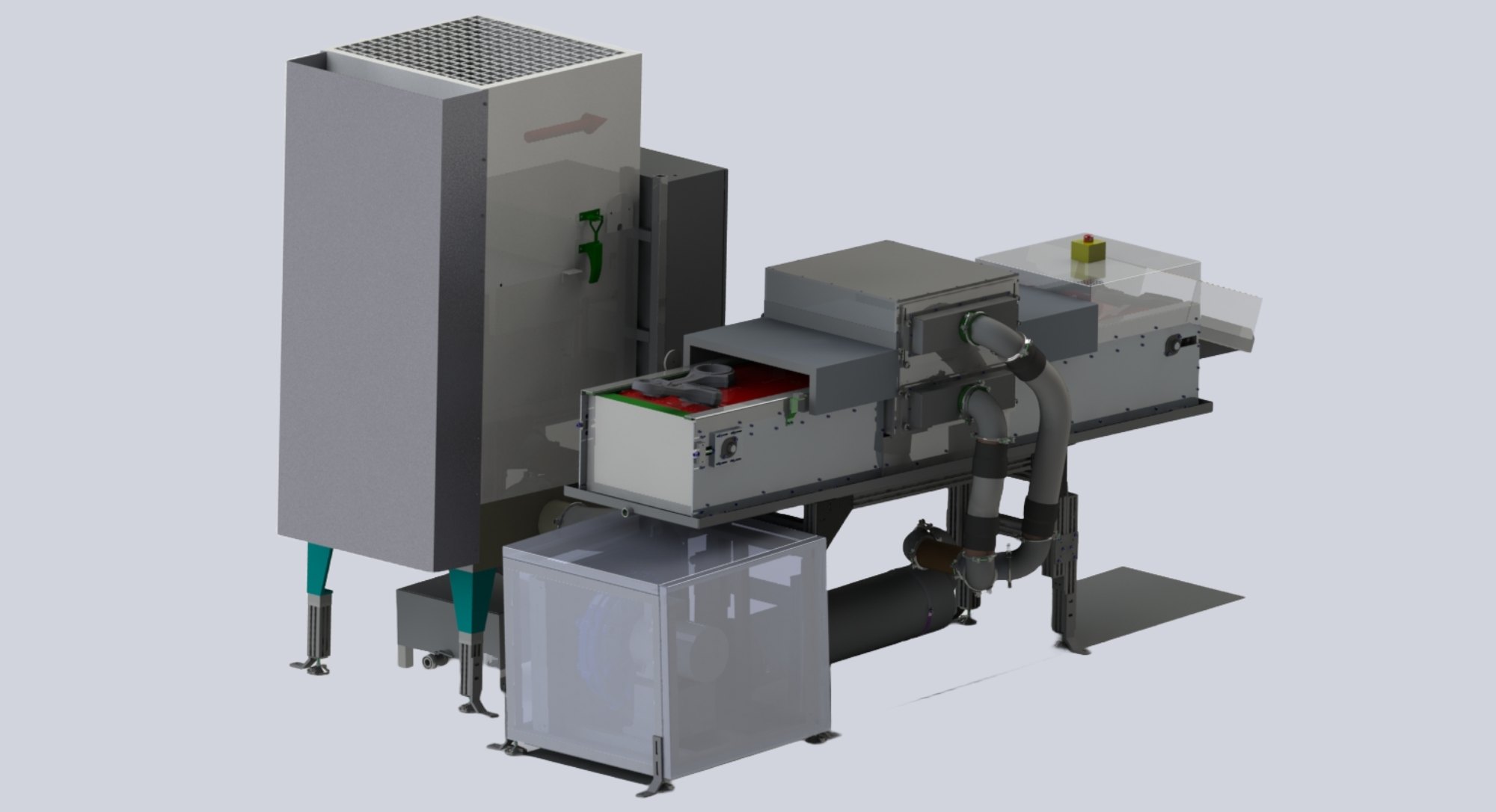

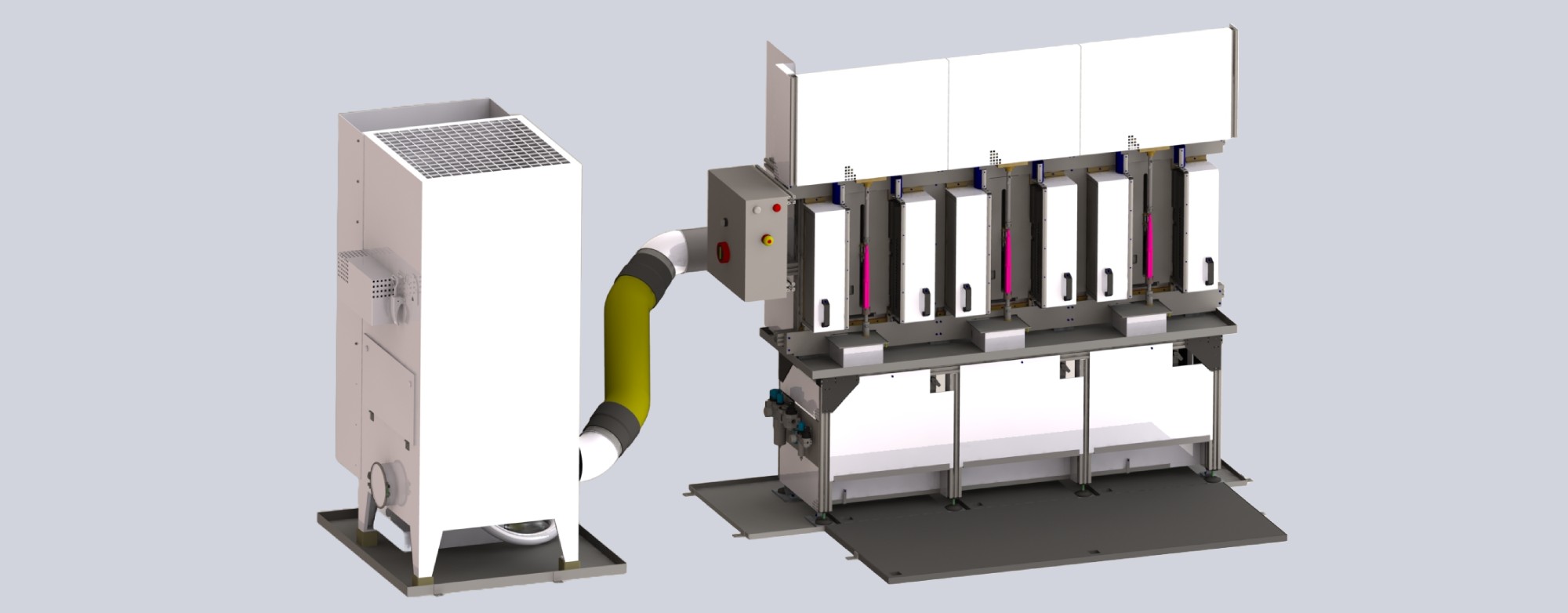

2. cleaning station for flat components / conveyor belt system

Flat components (e.g. gear wheels) are automatically guided through the cleaning chamber via a running conveyor belt.

A blowing air curtain and specially aligned blowing nozzles ensure the removal of cooling lubricant and build-up.

Highlights of this variant:

- Continuous component feed

- Alignment of components possible

- Automatic removal after the cleaning process

Perfectly suited for series production with high cycle rates.

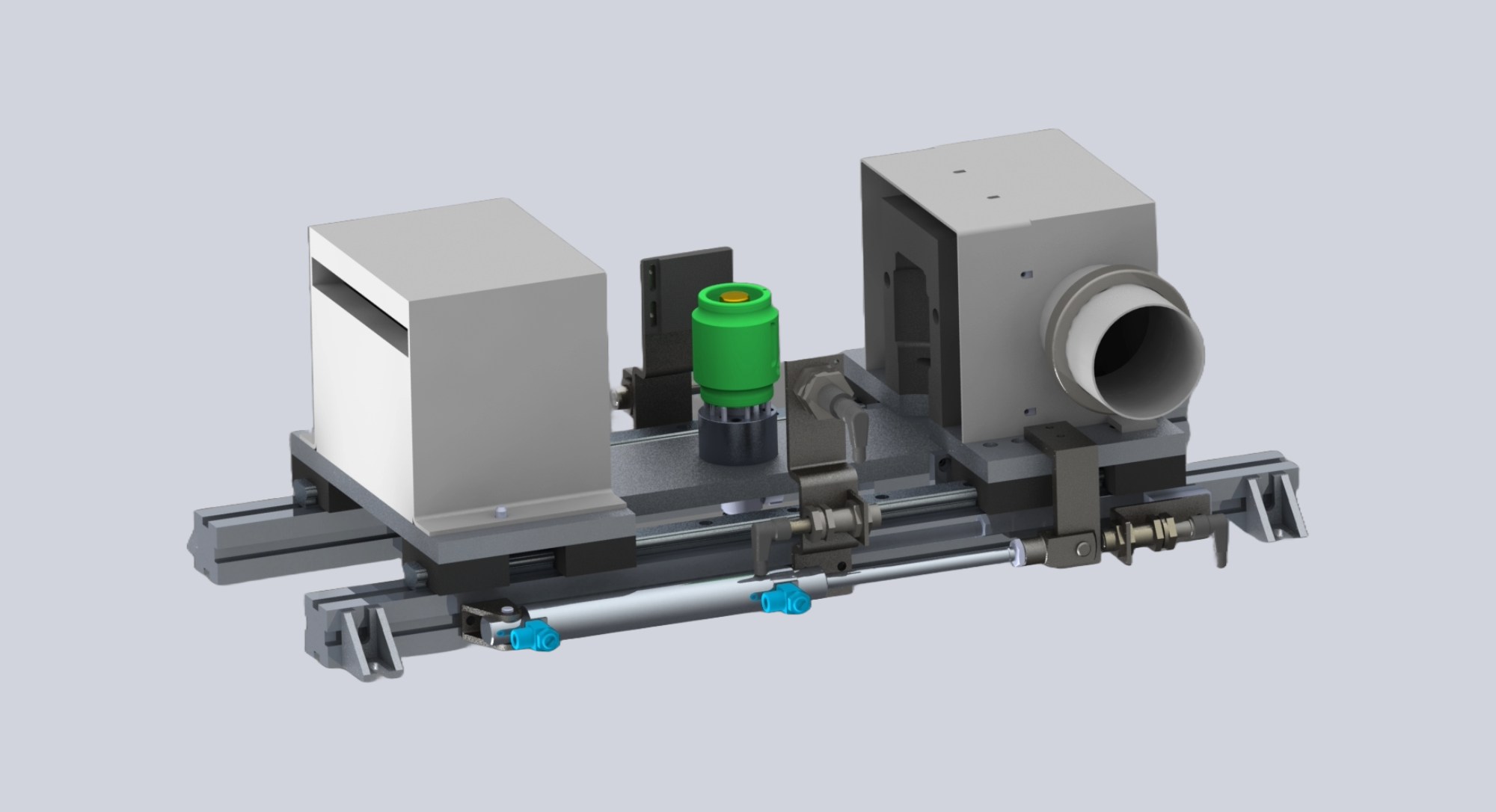

Aerosol separation & media recirculation

In both systems, aerosols are safely extracted, filtered in two stages and the separated cooling lubricant can be automatically fed back into the cooling lubricant circuit.

This makes our systems not only efficient, but also environmentally friendly and resource-saving.

Typische Werkstücke, die mit unseren Anlagen gereinigt werden

Shafts & rotating components:

Drive shafts, hollow shafts, eccentric shafts, gear shafts, rotor shafts, crankshafts, camshafts, intermediate shafts

Gear wheels & gearing elements:

Ring wheels, spur gears, pinion shafts, sun wheels, drive shafts, tripod spiders

Fields of application

- Automotive industry (conventional drives and e-motors)

- Machine and plant engineering

- Gearbox manufacturer

- Supply industry

- Precision parts production

- Laser processing / marking systems (component preparation)

Why Brüning pioneer?

- More than 110 years of experience in mechanical engineering

- Own development & production

- Customized cleaning concepts

- Integration into existing production lines

- Service and maintenance from a single source

Request a consultation & quote

Would you like to clean components more efficiently, improve service life or automate your production?

We develop the right dry cleaning solution for your application.